D301g Polystyrene Macroporous Weakly Basic Anion-Ion Exchange Resin for Hydrometallurgy and Pure Water Production

Description

Basic Info

| Model NO. | D301G |

| Warranty | 3 Years |

| MOQ | 1 Kg |

| Sample | Free |

| Keywords | Ion Exchange Resin |

| Type | Water Treatment Chemicals, Synthetic Resin |

| Packaging | 25kgs Bag |

| Specification | D301 |

| Trademark | LIJI RESIN |

| Origin | Cn |

| Production Capacity | 1000ton/Month |

Product Description

D301

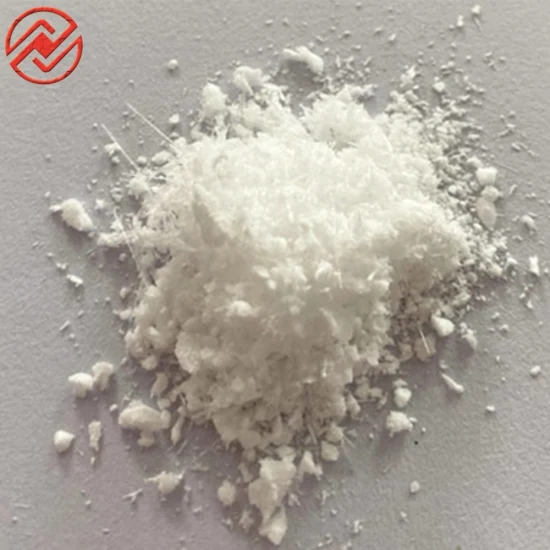

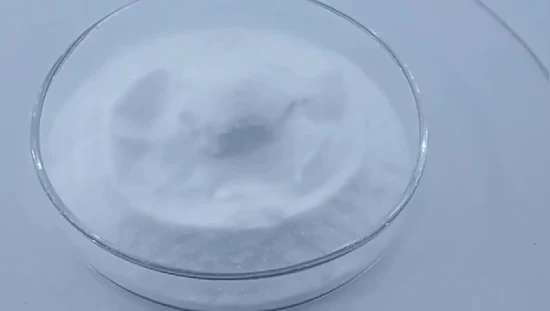

D301 is polystyrene skeleton macroreticular weakly basic anion exchange resin, containing the

-n (CH3) 2, weak alkaline resin in alkali type, easy to regenerate, working exchange capacity is

3 times of alkali type, nai organic pollution.Using unique and processes, and thus has high mechanical strength and chemical stability, widely used in water treatment and desalination of sugar decolorizing, can also be used for the refinement of organic matter and the treatment of wastewater containing chromium.

Application Corresponding Brands

Water treatment Purolite A100

Sugar decolorizing Dowex66

Refined organic matter Amberlite IRA-93

Wastewater treatment

Precautions

- Resin should be wet state preservation. The best temperature is above 0ºC. Resin should be put into a closed space or add in salt water of 5% or above if not used for a long time.Should be anti-freezing during transportation. Do not place heavy objects on the resin in case being crashed.

- Generally requires alkali- water - acid - water flow path for processing. Strict requirement needs three circulation before coming to final ion kenel.

- Need to consider different transformation expansion rate to set aside enough space to prevent resin overflow and ensure the appropriate liquid level height; Column diameter ratio should be within a reasonable range and avoid bias current; Use wet packed column or back-flushing to wash away bubbles inside resin layer.

- Before liquid going into the resin column, steps as flocculation, filtration, or sand-filtration should be taken so that it doesn't jam resin pore with suspended solids .

- Resin inside the column that hasn't been used for a long time should be storaged outside of the column after washing, or adding salt water in the salt resistant medium while keeping liquid level not dehydrated with usual backwashing to loosen resin in case of agglomeration.

Index

Name | Specification |

Appearance | Opalescent to light yellow opaque spherical beads |

Polymer Structure | Polystyrene crosslinked with divinylbenzene |

Functional Group | -N(CH3)2 |

Ionic Form | Free amine |

Weight Exchange Capacity | ≥4.8mmol/g |

Volume Exchange Capacity | ≥1.45mmol/ml |

Real Density (g/ml) | 1.03~1.06g/ml |

Bulk Density (g/ml) | 0.65~0.72 g/ml |

Water Retention Capacity | 48%~58% |

Particle Size Range | 0.315~1.25 mm≥95 |

Whole Bead Count(%) | ≥95% |

Reference Operation Conditions

Maximum operating temperature | 100ºC |

Resin filling height | 1~3m |

Operating velocity | 2~10BV/h |

Backwash velocity | 4~10BV/h |

Regeneration (desorption) velocity | 1~2BV/h |

Regeneration agent | 2BV3~5%HCI,2BV2~4% NaOH |

Index

Reference Operation Conditions

Reference Operation Conditions

Q1. What is the existing capacity to produce?

The annual output of cation and anion exchange resin is more than 20,000 tons,.

Q2. What are our advantages?

A. Our delivery time can be guaranteed. We use environment-friendly machine and built in national level chemical industrial park

B. We have complete production lines. We can custom made the products as customer requirements

C. We are near to Tianjin port and QingDao Port, so we have lower cost on transportation.

Q3. How about our quality of products?

We will test all the raw materials and arrange them into the factory after they are qualified. After the completion of production and testing, only qualified products can be packaged. We strictly follow the production process. Workers with more than 10 years of production experience, timely deal with problems and make registration, and issue 8D report.

Q4. Can I get free sample?

Yes, you can get 200g free sample, you just need to pay for the courier fee.

Q5. What's your delivery time?

15- 30 days after receiving your payment, depends on different products.

Q7. How should I pay?

We accept all kinds of payment ways. such as Alibaba trade Assurance, T/T, L/C,D/A,D/P, O/A,West Union.

Q8. Do you have other Water purification equipment and also can supply complete after-sales service.

We can also provide these products to meet your requirements, we also have a team to do the after- sales service.

Q9. Is it possible to custom the labels with my own design?

Yes, and you just need to send us your bag design, then you can get you want.

Prev: Pharmaceutical Intermediate 4-Bromo-2-Fluorobenzonitrile CAS 105942-08-3

Next: High Purity 99% Yk-11 Myostine/Myo Stain Yk11 for Weight Loss Muscle Gaining

Our Contact